Description

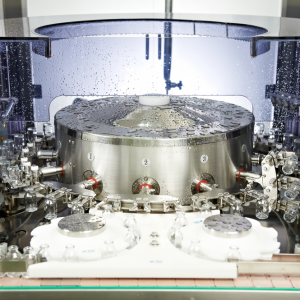

Glass Bottle Olive Oil Filling and Capping Machine

Glass Bottle Olive Oil Filling and Capping Machine

Olive Oil Glass Bottle Filling Capping and Labeling

The main reason why glass bottle olive oil filling machine is preferred so much is that Glass

Bottle is very healthy and durable. For this reason, many sectors, especially the food industry,

offer their products to their users in glass bottles of different sizes. Glass bottle olive oil filling

capping and labeling machine is used for oil filling capping and labeling operations.

Demand Evaluation

Glass bottle filling and closing machines are designed in accordance with the features requested

by the customer. Glass Bottle to be filled; daily filling capacity, safety band and label features

(Double or Single side) Glass bottle olive oil filling and closing machine stands out as the factors

considered in the design phase.

Design Phase

Technical painters are drawing glass bottle filling machines by considering the issues specified

during the glass bottle filling machine design. As a result of the meetings held between the

technical teams, the design takes its final form and the production phase is started.

Production Stage

The manufacturing process of the glass bottle olive oil filling machine is carried out by

coordination among technical teams. The products, whose purchasing process is completed,

are completed in the fastest time allowed by the production line and subjected to a series of

tests, and then the Glass bottle filling machine, which is ready, is shipped to the customer.

Working Principle

Glass bottles placed on a linear conveyor by hand or with the help of a robot are filled by the

number of filling nozzles determined according to the filling capacity. Glass Bottle filling After

the process is completed, the cap is placed on the bottles with the help of a vibration machine.

If the bottles whose caps are closed are requested, they are labeled as full or partial windings

by the labeling machine to be placed at the end of the line and collected in the collection tray.

What Can Be Filled With This Machine?

With this machine described above, Glass bottle milk filling, Glass bottle vinegar filling, Glass

bottle juice filling, plastic bottle vinegar filling, glass bottle kefir filling, plastic bottle juice filling,

Glass bottle turnip filling, etc. In addition to food products, fluid products such as antifreeze,

glass water, detergent filling can be filled.

https://www.expogi.com/dolum-ve-paketleme-tetripak-makine.html/

https://www.tetripak.com/tetripak-machine-gallery-cup-filling-machine/

Reviews

There are no reviews yet.